2024 Asphalt Material Submittal Requirments

-

Submittal requirements of individual municipality specifications shall be referenced for material submissions and mix design submissions unless otherwise modified in the KCMMB Asphalt Specification and/or KCMMB Asphalt Submittal Requirements.

-

FRAP stockpiles shall be prequalified in accordance with the current KCMMB Asphalt Material Specificationand the procedures described below.

-

Sampling: The following steps can be used to obtain representative samples from a FRAP stockpile:

-

Use a front-end loader to dig into the FRAP stockpile.

-

Empty the front-end loader onto a clean, flat surface to form a miniature stockpile.

-

Use the bucket of the front-end loader to level the surface of the miniature stockpile.

-

Use a square-ended shovel to dig into the level surface of the miniature stockpile.

-

Sample from three locations within the mini-stockpile.

-

Combine the samples from the three locations to provide a representative sample from the FRAP stockpile location.

-

Repeat the above steps to obtain the appropriate number of samples.

-

A minimum of ten samples shall be obtained from around the FRAP stockpile. Sample locations should be selected to provide a representative sample of the entire FRAP stockpile. The ten locations should encompass all sides of the stockpile.

-

-

Testing of the FRAP shall include the asphalt content and gradation of the FRAP samples. Asphalt content shall be determined utilizing both an ignition oven in accordance with ASTM D6307 and by solvent extraction in accordance with AASHTO T 164. When using the ignition oven, no aggregate or asphalt correction factor is needed for the FRAP stockpile materials. The gradation shall be determined using the aggregates remaining after ignition or extraction testing in accordance with ASTM C117 and C136. Half of the ten samples (5) shall be tested using ignition, and the remaining half (5) using extraction. The average difference of the two test methods will be an asphalt content correction constant that will be added or subtracted from the FRAP asphalt content determined by ignition during asphalt production and for the remaining prequalification tests. The aggregates from the ten gradation tests should not be thrown away in case further analysis is required, as described below.

-

Requirements for Prequalification of RAP Stockpiles Evaluation of the data will entail determining the average and standard deviation for the different test properties. Averages determined from testing of the ten locations should be used during the development of the job mix formula for the project. Target values for evaluation of uniformity are provided for three specific properties, including asphalt content, the percent passing the median sieve size, and the percent passing the No. 200 sieve. The median sieve size is the sieve with the percent passing closest to 50 percent. Table 1 provides the target standard deviations for these three properties. Test Properties from a uniform FRAP stockpile will have standard deviations at or below the target standard deviations. Table 1 also provides maximum allowable standard deviations.

Table 1: Target and Maximum Allowable Standard Deviations

RAP Property

Target Standard Deviation

(%)Maximum Allowable Standard Deviation

(%)2Asphalt Content (%)

Less than 0.5

0.75

% Passing Median Sieve1

Less than 5.0

7.5

% Passing No. 200 Sieve

Less than 1.5

2.0

1Median Sieve is the sieve closest to having an average of 50% passing

2Maximum allowable value

.

-

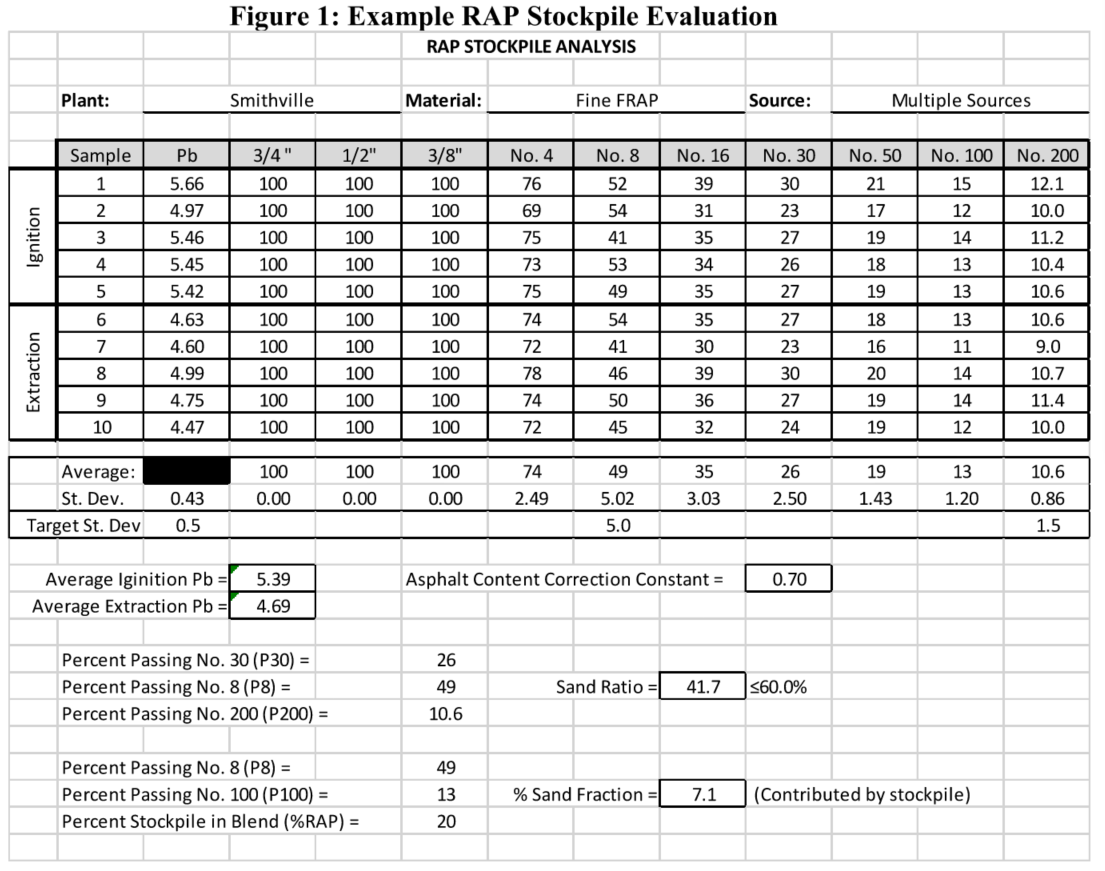

Figure 1 provides an example spreadsheet used for evaluating the data. For this example, the No. 8 sieve is the median sieve because it is the sieve with the percent passing closest to 50 percent. As shown in Figure 1, the asphalt content meets the target standard deviation as the calculated standard deviation is less than 0.5 percent (0.43 percent). The median sieve (No. 8) has a standard deviation slightly above the target of 5.0 percent. However, this standard deviation is not above the maximum allowable standard deviation of 7.5 percent. For the No. 200 sieve, the calculated standard deviation is 0.86 percent which is less than the target standard deviation.

-

Fine Aggregate Fraction of the FRAP Stockpile

-

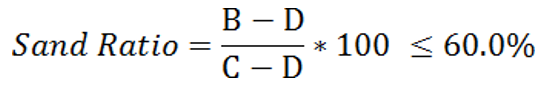

Using the results of the FRAP Stockpile Analysis (Figure 1), calculate the Sand Ratio using the following Equation. If the Sand Ratio is above 60 percent, it suggests a relatively large percentage of natural, uncrushed fine aggregate exists within the RAP stockpile.

Where:

B = % of Gradation passing the No. 30 Sieve

C = % of Gradation passing the No. 8 Sieve

D = % of Gradation passing the No. 200 Sieve

-

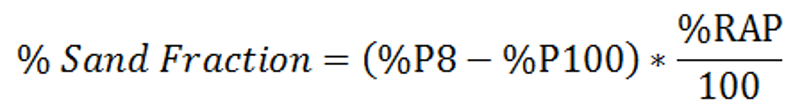

If the Sand Ratio is above 60.0 percent, calculate the percentage of fine aggregate contributed to the total aggregate blend by the fine aggregate fraction of the RAP stockpile as follows:

Where:

% Sand Fraction = % Sand Fraction from FRAP stockpile in Total aggregate blend

%P8 = percent of gradation passing No. 8 sieve

%P100 = percent of gradation passing No. 100 sieve

%RAP = percent of FRAP within the total aggregate blend -

If the combined % Sand Fraction of all FRAP stockpiles plus the percentage of natural sand within the total aggregate blend is more than 25.0 percent, a Fine Aggregate Angularity test shall be conducted. Using the aggregates remaining from the ten FRAP stockpile evaluation tests, first, conduct a specific gravity and absorption test 600-4 on the fine aggregate fraction in accordance with ASTM C128. After determining the bulk specific gravity of the fine aggregate fraction of the FRAP aggregates, conduct the Fine Aggregate Angularity (FAA) test on the entire aggregate blend in accordance with Method A of ASTM C1252. The FAA of the combined FRAP and natural sand shall be above 45.0%.

-

-

-

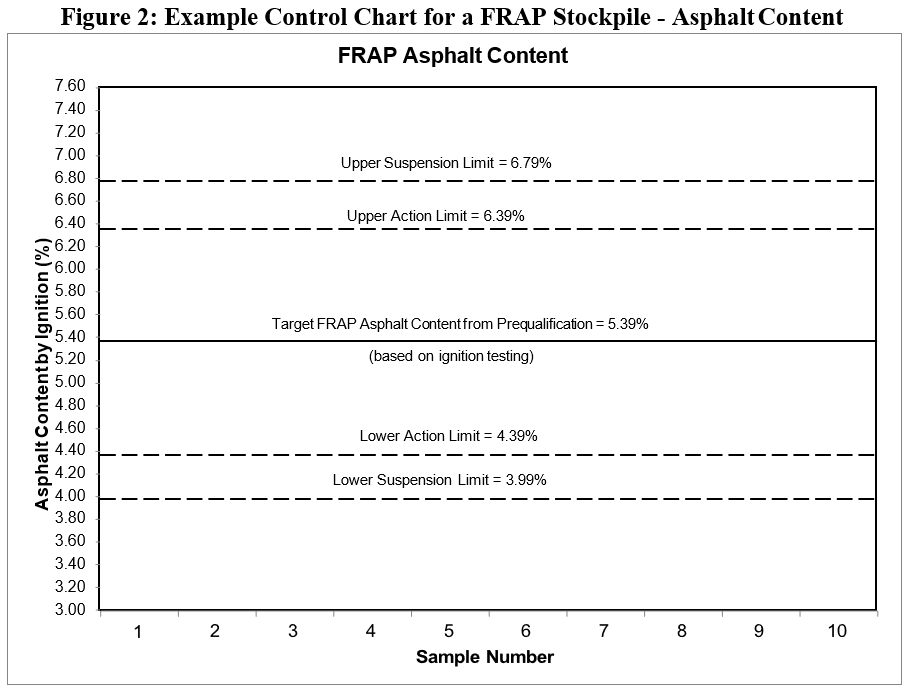

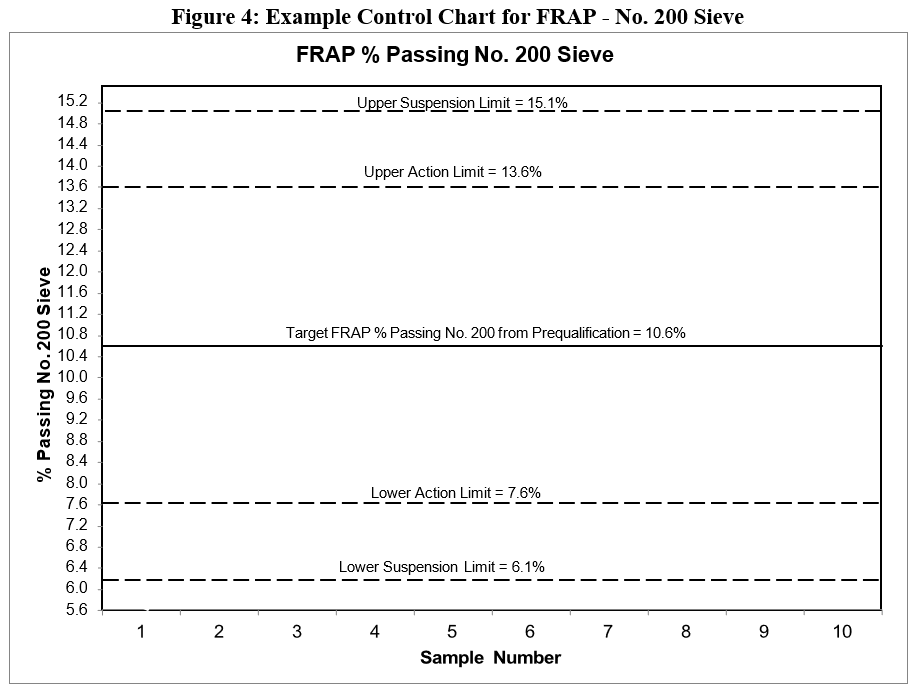

The Contractor shall maintain Control Charts for the percent passing the median sieve, percent passing the No. 200 sieve, and asphalt binder content for each FRAP stockpile contained within the approved Job Mix Formula (JMF). The Control Charts will use the average value of each of the three properties determined from the prequalification of the FRAP stockpile(s) as the target values.

-

Asphalt binder will be determined using either an extracted value or an adjusted ignition value as described above. The Control Charts will use the average value of each of the three properties determined from the prequalification of the FRAP stockpile(s) as the target values. Table 2 presents Action Limits and Suspension Limits for use with the Control Charts. Examples of appropriate Control Charts are shown in Figures 2 through 4. Target values within these figures are the averages within the example shown in Table 2.

Table 2: Action and Suspension Limits for FRAP Stockpiles

Property

Action Limits

Suspension Limits

FRAP Asphalt Content

± 1.0%

± 1.4%

% Passing Median Sieve

± 10.0%

± 14.0%

% Passing No. 200 Sieve

± 3.0%

± 4.5%

-

All submittal information shall be submitted to individual municipalities before use.

Josh Miller

George Butler Associates, Inc.

Tel. 913.577.8254

Lucas Rosenbaum

George Butler Associates, Inc.

Tel. 913.577.8271